Online Jewelry Training Classes for Metalsmiths

Some jewelry designs call for tubing that are then curved into the desired design. At the same time these designs need to be light requiring like hollow hoop earrings.

The problem with tubing which is not supported on the inside, will deform when bent into a curve.

This free jewelry tutorial follows the same format as in the paid for pdf jewelry tutorials. This gives you a good insight into the to technical teaching methodology.

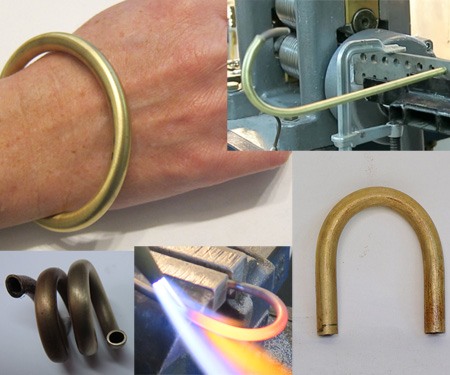

There are quite a few methods of bending hollow tubing, starting with a specific tool like the one pictured.

How ever, this tool can at most bend a few diameters of tubing into circles shapes.

Another way of bending small diameter tubing into circles is to fill the tube with a supporting material that is either left in the tubing ( like bitumen) or is removed once the bending process is complete.

Water, ice salt and sand are other materials that are successfully used..

A mixture of bismuth, lead, tin and cadmium which is commercially available and is called Cerrobend, works very well to bend small diameter tubing into virtually any shape.

It melts at about 70 C ( 158 °F) and when rapidly chilled, one will get a very fine-grained structure, meaning that it is very ductile.

To remove it, it is heated in hot water, poured out and the residual remains are removed with compressed air.

Bending small diameter tubing using a steel former.

In my first example, I use handmade silver tubing. Handmade tubing has a soldered seam.

I have a free tutorial on Making Tubing that shows the process.

In this case I am using 4 mm stainless steel rod and the silver tubing has been drawn down to fit as tightly as possible.

( I start bigger and the draw it down until the former fits)

Some general purpose grease has been applied to the steel former before the silver tube is slipped over.

The end of the former is bent slightly to the one side to allow the curl of the tube past once it completes a full circle.

The seam must be on the inside of the curl.

If it is not, the tubing will most likely tear on the seam as it is drawn through the draw plate.

The steel former is placed in the appropriate sized hole that allows the former to pull through but stops the tubing doing the same.

This picture shows the former about to be pulled through.

When the curl reaches the drawplate, the rod is removed and a steel spring is slipped over the rod and then it is re inserted and pulled further until the curl pops off

The spring is easily removed afterwards.

I have very successfully made tubing of up to 7 mm outside diameter.

This picture shows me bending 6 mm stainless steel rod for the former.

Here is commercially bought brass tubing with an inside diameter of 6 mm and an outside diameter of 7 mm , which means that the wall thickness is 0.5 mm.

One would think that such a relatively large diameter would need a strong force to draw it through the draw plate, but it needs surprisingly little.

Even though a draw bench is required for 6 mm tubing, I have successfully drawn 3 mm tubing through using just hand power, so the lack of such a machine does not necessarily limit one.

Here is the 7 mm tubing being shown off as a bangle.

The weight of the bangle is 12 grams.

When the former is a lot smaller that the inside diameter of the tubing, say a 3 mm former in a 4 mm inside diameter tubing, then the profile becomes an oval.

This in itself is not a bad thing, because were one to make a bangle or a ring, then that profile lends itself to more comfortable wear, much like the 'comfort shape' of a ring profile.

I had some square square tubing lying around, so I decided to draw it and see what happens.

So I rolled some 6 mm stainless steel rod down to about 3 mm square in my rollers.

I would have thought stainless steel would dislike rolling, but surprise surprise, it rolled down to 3 mm from 6 mm without even being annealed.

It drew down perfectly in terms of curling.

But the profile was slightly deformed.

I suspect that the deformation was caused by the fact that the former that I rolled out was a bit too loose inside.

A tighter fit might give a better result.

Another example of a wax carved woman figure with robes which is then cast into silver.

or select other projects from Jewelry Making Tutorials List

Click the link to receive your free PDF version of this tutorial on How to Bend Tubing into a Circle, which will be emailed to you within 4 - 12 hours.

If you have any questions or wish to be notified of any new tutorials that are posted, email me.

This content is the intellectual property of Hans Meevis. More information on our Copyright and Privacy Policy