Online Jewelry Training Classes for Metalsmiths

Cutting cabochons or cabbing as it is also called, is a good place to start when you're want to cut your own gem material. It is good to practice on glass or pre-slabbed minerals before attempting to cabbing more valuable rough gemstone material.

This is step by step lapidary instruction on how to make a cabochon from a rough gemstone by preforming, cutting, shaping and polishing it to a highly lustrous, smooth light reflecting convex surface.

I select a piece of rough gem material.

In this case it is called Sugilite, a cyclo silicate mineral allied to the manganese mine in the middle of the Kalahari desert in the northern Cape in South Africa. The place is called Hotazel.

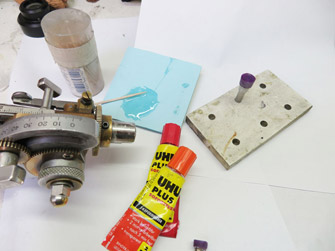

The piece is preformed on a diamond lap and then glued to a dop stick with two component epoxy.

The stone is cut round using an Imahashi gem cutting machine.

I use my gem cutting machine because I have it, not because it is essential to use.

A V block, with a wooden dowel stick would work just as well.

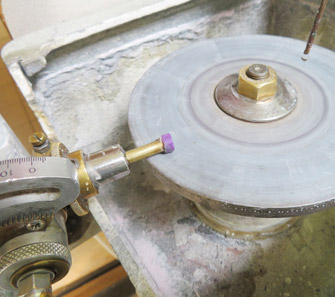

Final smoothing on a 1200 grit diamond lap.

I remove the dop from the Imahashi tang and shape the dome of the stone by hand.

After rough shaping with 220 grit and then final smoothing with 1200 grit.

From the 1200 diamond lap, I go to a hard felt lap charged with a mixture of 1200 grit diamond powder and Vaseline.

From there I then go to a hard felt lap charged with 50,000 grit and Vaseline.

The Sugilite cabochon ready for setting in jewelry.

Here is a short video clip showing how to Remove Scratches on a Cabochon

or select other projects from Jewelry Making Tutorials List

If you have any questions or wish to be notified of any new tutorials that are posted, email me.

This content is the intellectual property of Hans Meevis. More information on our Copyright and Privacy Policy