Online Jewelry Training Classes for Metalsmiths

Making a rubber mold forms part of the lost wax casting process. A mold is made of a “master ring” the original piece from which many wax copies can be injected and cast .

I demonstrate how I make the mold of this ring using a somewhat different approach. Cutting a rubber mold is not easy. Apart from the fact that the piece that has been molded has to be cut out so that subsequent injected waxes can be removed easily, the mold also has to be cut with 'locks' so that the parting lines are minimized.

The following pictures do not show how I cut any given piece out of the cured rubber, but rather what I do for my locks.

This free tutorial follows the same format as all my other free and premium tutorials. This gives you a good insight into the technical teaching methodology.

I always solder my sprue on. Normally the sprue would be attached at the bottom of the ring, but in this case the ring is very thick on the top, and so the sprue is attached to the heaviest section. This prevents the wax from shrinking as it cools down in the mold.

This is the ring in a standard 50mm mold frame.

I start packing the mold. I use Castaldo Gold rubber. And I buy the pre-cut slices. Much easier.

I draw the area out and use a pair of scissors to cut it out.

I have a supply of Blind rivets. These are available at hardware stores. I have found these to be far better than commercially made locking pins.

Then I mark out where I want to have the rivets positioned.

I use a leather hole making pliers to make the holes in the rubber. I will take two layers of rubber and punch the both at once. That way all the holes are aligned

Then I push the rivets through the first cut-out rubber sheet.

I put the punched layer on.

Then the second punched layer. Because I punched both sheets at once, the holes are perfectly aligned This is essential when I use five or six rivets. The rest of the layers are then put on top and the mold is vulcanized in the normal manner.

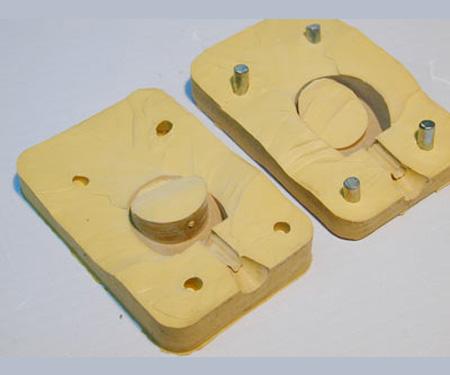

The mold is cut in the normal manner. The rivets tend to 'float' a bit when the mould is being vulcanized. This is good, because when the mold is put together, it 'snaps' shut.

The cut mold. No locks have to be cut and parting lines are minimal.

or select other projects from Jewelry Making Tutorials List

If you have any questions or wish to be notified of any new tutorials that are posted, email me.

This content is the intellectual property of Hans Meevis. More information on our Copyright and Privacy Policy